Classification of Types of Bricks Based on Material

Bricks are categorized into two groups based on their material:

Pressed Bricks

The reason for naming this type of brick “pressed” lies in its production process. Initially, the clay for these bricks was shaped by hand, and workers would manually press the clay into the corners of the mold using a special type of mud. The dimensions of pressed bricks are typically 5×10×20 cm or 5.5×11×22 cm. Pressed bricks are suitable for all types of construction work, including decorative brickwork, vaulted ceilings, load-bearing walls, and partition walls.

For more information, feel free to check out our Brick facade

Machine-Made Bricks

Machine-made bricks, also known as perforated bricks, have 8 to 10 holes on their larger surface, each with a diameter of 1.5 to 2 cm. In the Iranian market, these are commonly referred to as “8-hole” or “10-hole machine-made bricks.”According to Standard No. 7 of the Iranian Institute of Standards and Industrial Research, these holes must pass through the entire thickness of the brick, and the total cross-sectional area of the holes should not exceed 25% of the larger surface of the brick. Additionally, the distance between the holes and the edge of the brick, as well as the distance between the holes themselves in any dimension, must not be less than 30% of the length of that dimension.

The purpose of these holes is to allow mortar to penetrate vertically into the brick during construction, which increases the strength of the wall.For constructing load-bearing walls, this type of brick is often used because the holes in the brick can accommodate reinforcement bars (rebar), making it possible to create reinforced brick walls. Such reinforced walls are designed to withstand seismic forces.The material of machine-made bricks is much more brittle and fragile compared to pressed bricks, and their absorption capacity is lower.

Due to their brittleness, they cannot be chiseled or shaped easily. Furthermore, because they have a low absorption capacity and do not bond well with mortar, they are not suitable for use in vaulted ceilings.The dimensions of these bricks are 5.5×11×22 cm. Their edges are straighter, and their surfaces are smoother compared to pressed bricks, which makes them more precise and uniform in construction projects.

Alumina Bricks

This term refers to a wide range of refractory bricks that contain between 45% and 99% aluminum oxide (Al₂O₃).

Refractory Bricks

Refractory bricks are essentially a type of porcelain made from various types of fire-resistant clays. Porcelain is a high-quality ceramic material that has a finer and denser structure compared to earthenware. The firing temperature for refractory bricks is approximately 1500°C. The different types of refractory bricks and their applications are as follows:

For more information, feel free to check out our refractory bricks (fire brick)

Alumina Refractory Bricks

These bricks contain a high percentage of alumina (Al₂O₃). They are made from a mixture of kaolin, bauxite, and corundum, which contains more than 70% alumina. The firing temperature for these bricks ranges from 1200°C to 1800°C. This type of brick is primarily used to line the inner walls of steel-melting furnaces. Due to their resistance to alkaline materials, they are also used as lining for the inner walls of cement and glass kilns.

Silica Refractory Bricks

The main component of these bricks is silica clay, commonly known as quartzite. Quartzite consists of 95% silicon dioxide (SiO₂) along with small amounts of alumina (Al₂O₃), iron oxide (Fe₂O₃), titanium dioxide (TiO₂), potassium oxide (K₂O), and sodium oxide (Na₂O). In the past, these bricks were used to line the inner walls of steel production furnaces. However, due to their high thermal conductivity and impermeability to gases, they are now mostly used for lining the inner walls of glass-melting furnaces in glass manufacturing plants, gas-fired coke ovens, and ceramic production kilns.

Special Refractory Bricks

These are a specific type of refractory brick designed for specialized industrial applications. They are made from compounds of transition metals. The most common types in this category include:

Chromium-Corundum Refractory Bricks

These bricks contain 5–10% chromium oxide (Cr₂O₃) and 90–95% aluminum oxide (Al₂O₃). They are highly resistant to alkaline substances and are used to construct the inner lining of blast furnaces in steel production.

Zirconium Refractory Bricks

These bricks are made from natural zirconium sulfate with a small amount of alumina added to quartz. Their primary applications include aluminum-melting furnaces, molten glass tank furnaces, and kilns operating at very high temperatures.

During the production process, zirconium sulfate is melted with lime, and impurities are separated as calcium silicate, resulting in pure zirconium oxide (ZrO₂).

Zirconium oxide has excellent thermal resistance, making it ideal for manufacturing crucibles used in metal melting in steel industries and as a neutron reflector in nuclear reactors.

Chromium Oxide Refractory Bricks

These bricks contain 95% chromium oxide (Cr₂O₃) and are made using synthetic Cr₂O₃. They are primarily used in the construction of glass-melting furnaces in the glass industry.

For more information, feel free to check out our fireclay

Alkaline Refractory Bricks

These bricks consist of silicon dioxide (SiO₂) and magnesium oxide (MgO). Magnesium oxide is produced by heating natural magnesium carbonate (magnesite) or dolomite at temperatures ranging from 550°C to 1800°C.

Alkaline refractory bricks are used to line the inner walls of open-hearth steel furnaces, rotary kilns in cement factories, the upper sections of glass-melting furnaces, and in non-ferrous metal industries.

Fused Bricks (Fire-Clay Bricks)

These bricks are made from clay that does not become pliable at temperatures exceeding 1000°C. They are kept in the kiln for an extended period so that the clay particles slightly melt and fuse together, forming a solid, cohesive brick. These bricks must not become pliable in the kiln’s heat, and there should be a significant difference between the melting and softening points of the clay used for fused bricks. To reduce the melting point, a fluxing agent—usually iron oxide—is added. In addition to acting as a flux, iron oxide gives the brick a red to black color when fired at temperatures between 1000°C and 1200°C.The beige color of fused bricks results from a low iron oxide content and a higher presence of lime and alkaline materials. These bricks must be hard, not brittle, free of cracks, resistant to impact, and should not chip or flake. They should have low abrasion, a rough texture, and even the abraded areas should remain rough. The fractured surface of the brick should not appear glassy but rather granular and dense. Fused bricks must also be resistant to frost and chemical substances. The compressive strength of fused bricks should not be less than 35 N/mm². Structural fused bricks should absorb no more than 6% of their weight in water, while paving bricks should absorb no more than 4%. The specific gravity of fused bricks must exceed 1.9.Fused bricks used for paving roads and sidewalks must have high impact resistance, minimal abrasion, and a rough texture that remains rough even after wear. These bricks are also used for lining tunnel walls and sewage channels.

For more information, feel free to check out our Brick carpet floor

Glazed Bricks

Glazed bricks are made in the same way as regular bricks, with the only difference being that their surface is coated with a ceramic glaze. These bricks are used exclusively for building facades. The smooth and polished surface of glazed bricks prevents water from penetrating the brick, making them more resistant to chemical substances. However, if the glaze has a different coefficient of expansion and contraction than the brick itself, the surface may crack, resulting in an unattractive and uneven appearance. Glazed bricks are primarily used to enhance the aesthetic appeal of building facades and to increase their resistance to weathering and erosion.

For more information, feel free to check out our Glazed brick facade

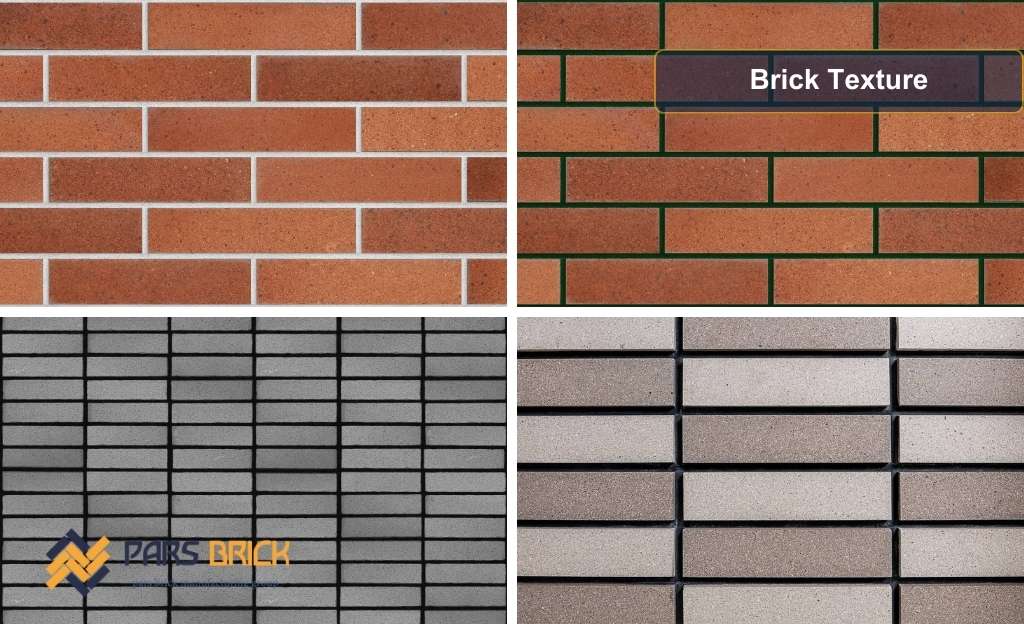

Classification of Bricks Based on Color

When bricks are used for facades, their color becomes an important factor. For façade work, bricks are available in light yellow, referred to as “white bricks,” darker yellow, known as “peach bricks,” and shades of red, ranging from bright red to deep red.Between approximately 1940 and 1960 (1320–1340 in the Iranian calendar), a type of multicolored brick in shades of red and yellow, called Bahareni Brick, was introduced to the market. These bricks were produced in a kiln named after the same type of brick.The thickness of bricks used for facades may range from 3 to 5 centimeters, but the other two dimensions are typically the same as those of pressed or machine-made bricks, measuring 10×20 cm.The color of these bricks is influenced by the way they are arranged in the kiln, the firing process, and the control of surfaces that are in direct contact with the flame. It is also affected by the metal oxides present in the raw materials of the bricks, such as different types of iron oxides. Producing colored bricks requires greater care and cost during the preparation of raw materials, as well as in the molding and drying stages.

For more information, feel free to check out our traditional brick