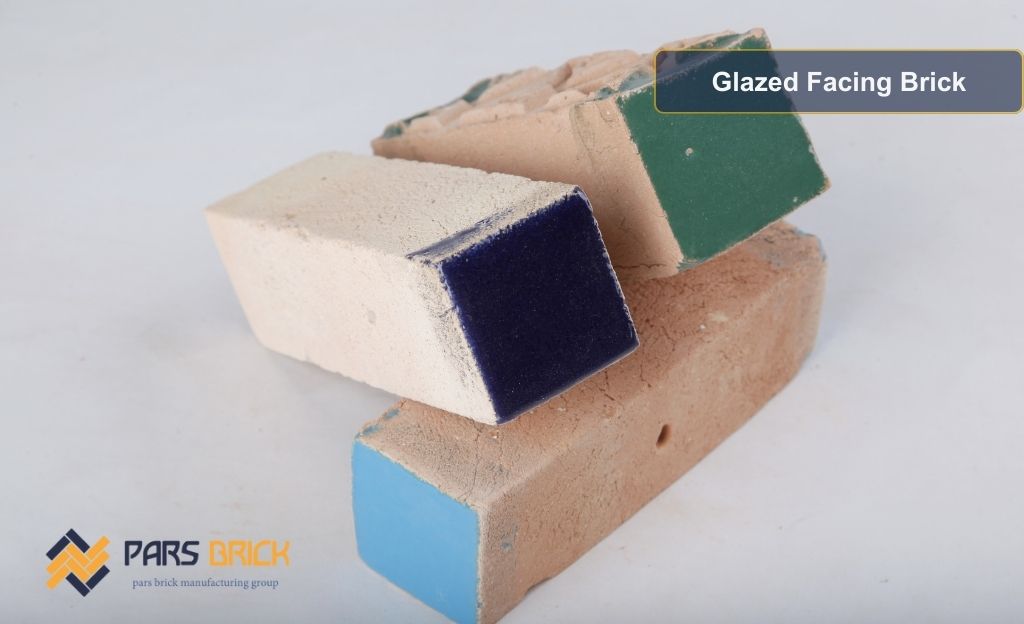

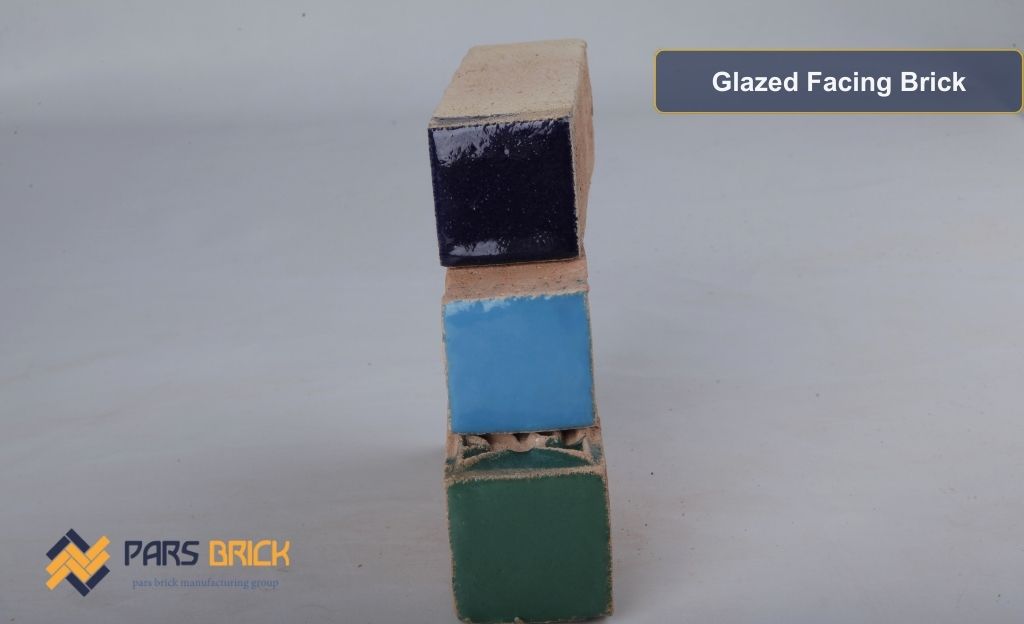

Glazed Facade Brick

In the brick production industry, glazed facade brick is one of the oldest types of colored brick that has been produced. The glaze is applied to the Qazvin brick, which was primarily used in buildings, palaces, and religious centers in ancient times.

Glazed bricks do not have specific dimensions due to the variety of shapes and designs they come in.

Production Method of Glazed Facade Brick

The production process of glazed facade brick is as follows:Initially, the glaze is poured onto the brick, and its surface is smoothed out. After the initial setting, the brick is placed inside a kiln for a second firing to ensure the glaze is properly baked.The firing temperature of the glaze varies depending on the color and type of glaze used.

The components of the glaze include silica and flint stone, along with various oxides for different colors. Once melted, silica and flint take on a liquid form that appears smooth and glossy, similar to glass.

The color of the glaze can be altered by mixing different metal oxides with the glaze.Various oxides such as copper, chromium, iron, tin, lead, and cobalt are used. The amount of oxygen during production also affects the glaze color; for example, a high oxygen level in copper produces a turquoise color, while less oxygen results in a red color.

These colors can also be adjusted by regulating the temperature.Glaze colors are categorized into matte, glossy, and textured finishes.Due to the glaze on its surface, glazed bricks have high resistance, making them easy to clean. They exhibit excellent resistance to heat, cold, weather conditions, and chemicals.Glazed bricks are commonly used for the facades of various modern and traditional buildings, kitchens, bathrooms, and cultural and religious centers.

For more information, feel free to check out our Brick facade