Types of Bricks Based on Material Composition

Pressed Bricks:

Pressed bricks are typically used in the structural and foundational work of buildings and are produced manually (known as “grit bricks”). These bricks are suitable for various construction tasks, including masonry, arch construction, load-bearing walls, and partition walls.Currently, the construction industry in Iran extensively utilizes pressed bricks.

These bricks are often shaped by hand and fired in local kilns, resulting in standardized dimensions based on extensive experience accumulated over time, typically measuring 5.5 × 10 × 22 cm.The prevalence of pressed bricks in Iran has compelled the machine-made brick industry to align its dimensions closely with those of pressed bricks. Consequently, the current machine-made bricks in Iran also measure 5.5 × 10 × 22 cm. Any significant changes to the dimensions of machine-made bricks would require a reevaluation of the dimensions of pressed bricks.

Therefore, as long as pressed bricks maintain their essential role in the construction industry, the dimensions of machine-made bricks will continue to follow those of pressed bricks. This type of brick is suitable for all construction tasks, including masonry, arch construction, load-bearing walls, and partition walls.

For more information, feel free to check out our Brick facade

Machine-Made Bricks:

Machine-made bricks, also known as hollow bricks, feature 8 or 10 holes on their larger surface, each with a diameter of 1.5 to 2 centimeters. In the Iranian market, they are commonly referred to as eight or ten-hole machine-made bricks. According to Standard No. 7 of the Institute of Standards and Industrial Research of Iran, these holes must penetrate the entire thickness of the brick, and the total cross-sectional area of the holes should not exceed 25% of the larger surface area of the brick. Additionally, the distance of the holes from the edge of the brick, as well as the distance between the holes in any dimension of the brick, should not be less than 300% of the length of that dimension.The purpose of these holes is to allow mortar to penetrate vertically into the brick during wall construction, thereby enhancing the wall’s strength. In load-bearing walls, these bricks can be reinforced with rebar through the existing holes, making them suitable for earthquake-resistant brick walls.Compared to pressed bricks, machine-made bricks are much more brittle and fragile, and they have lower absorbency. Due to their brittleness, they cannot be easily shaped with a chisel, and because they lack significant absorbency, they do not adhere well to mortar, which makes them unsuitable for arch construction. The dimensions of these bricks are 5.5 × 11 × 22 cm. Their sides are more angular, and they have smoother surfaces compared to pressed bricks.

For more information, feel free to check out our Red brick facade

Clay Bricks:

This category of bricks is manufactured with utmost precision in terms of construction, shape, color, and technical specifications, and they are utilized throughout various parts of a building based on their shape. Due to their low water absorption, ten-hole clay bricks are often used in their hollow forms to ensure adequate adhesion with mortar. Another significant characteristic of these bricks is their lightweight nature, which contributes to increased efficiency in construction speed.

Old Bricks:

These types of bricks were produced in large pieces and, despite being made by hand, they maintained a good level of quality.

Military Bricks:

These bricks, measuring the equivalent of four ordinary bricks at 5 × 50 × 50 cm, were historically used in the floors of barracks.Khatayi Bricks:

Measuring 5 × 25 × 25 cm, Khatayi bricks were commonly used in older buildings for flooring in courtyards and other areas.

For more information, feel free to check out our pink perforated facing brick

Flat Bricks (Iranian Square Bricks):

Larger than military bricks, these flat bricks were primarily used for paving floors.

Shakari Bricks (Water Reservoir Bricks):

Also known as water reservoir bricks, these are resistant to moisture and were traditionally used in constructing water storage tanks.

Glazed Bricks:

Glazed bricks and the art of glazing have been a prominent feature of Iranian architecture for centuries. One of the primary benefits of glazing is the enhanced resistance it provides against weathering and erosion. The smooth and polished surface of the glaze prevents water from penetrating the brick and makes it more resistant to chemical damage.The glazing process typically occurs at the final stage of drying. During this process, a layer of a specially formulated mineral compound is sprayed onto one or more surfaces of the brick. The glaze dissolves and fuses into the brick at a specific temperature. Once fired, the result is a glossy and polished finish.The choice of raw materials in producing glazed bricks is critically important. If the coefficient of expansion and contraction of the glaze does not match that of the brick, the glaze will quickly crack.

For more information, feel free to check out our Glazed brick facade

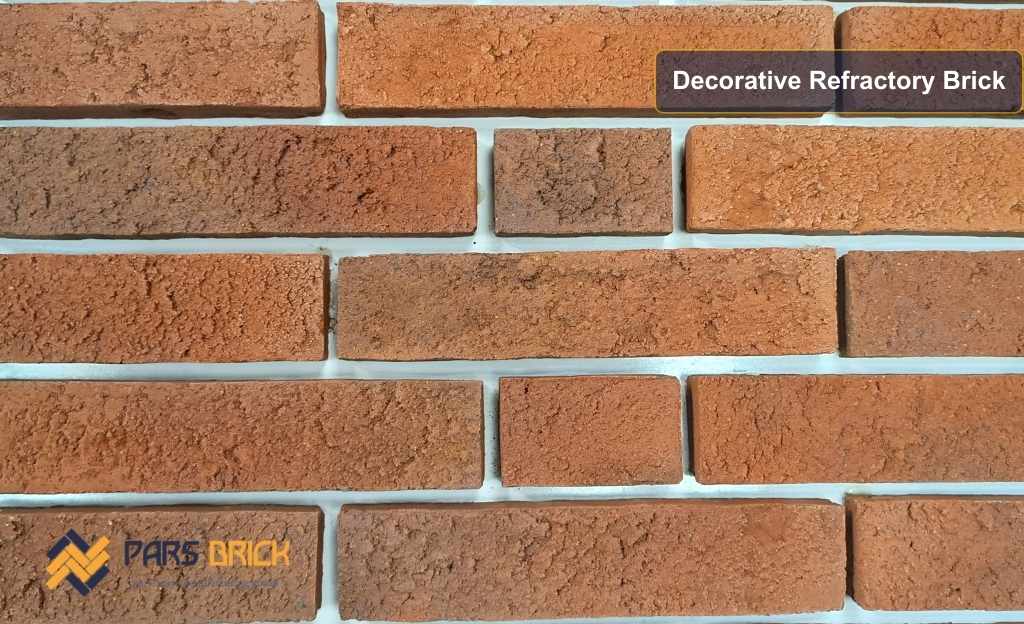

Refractory Bricks:

The raw materials and production process of refractory bricks vary depending on their intended use, kiln temperature, chemical environment, pressure, abrasion, and temperature fluctuations. They are manufactured using minimal fluxing agents and are essentially made from various types of fireclay.Facade refractory bricks are not exclusively for the exterior of buildings; they can also be used in interior spaces and humid environments such as bathrooms, kitchens, and even flooring.

Sand-Lime Bricks:

The primary component of these bricks is calcium silicate, made from a mixture of lime and silica sand, which is shaped under conditions of pressure and steam. These bricks should not be exposed to acidic environments or strong salts. They shrink during the drying process and, due to their higher water absorption compared to other bricks, they are not recommended for use in foundations or base layers.

Fused Bricks (Fire-Clay Bricks):

These bricks are made from clay that does not become plastic or lose its shape at temperatures exceeding 1000°C. They are kept in the kiln for a longer duration to allow the clay particles to partially melt and fuse together, forming a solid, unified piece. The clay used for fused bricks must not become plastic in the kiln, and there should be a significant difference between the clay’s sintering (melting) point and its plastic deformation temperature. To reduce the sintering temperature, fluxing agents—most commonly iron oxide—are added to the mixture. In addition to acting as a flux, iron oxide also contributes to the color of the brick, turning it red to black when fired at temperatures between 1000°C and 1200°C. A pale color in fused bricks typically indicates a low iron oxide content and a higher presence of lime and alkaline materials.These bricks must be extremely durable, resistant to cracking, and not brittle. They should withstand impact without chipping, exhibit low wear, remain rough even after abrasion, and their broken surfaces should not appear glassy but rather granular and dense. Fused bricks must also be resistant to frost and chemical substances.The compressive strength of fused bricks must not fall below 35 N/mm². For construction bricks, water absorption should not exceed 6% of their weight, while for paving bricks, it should not surpass 4%. The specific gravity of fused bricks should be greater than 1.9.Fused bricks used for paving roads and sidewalks must exhibit high impact resistance, very low wear, and retain their rough texture even after abrasion. They are also utilized for cladding the walls of tunnels and sewage systems due to their durability and resistance to harsh environmental conditions.

For more information, feel free to check out our Brick faced L